Threats of a non-systemic approach

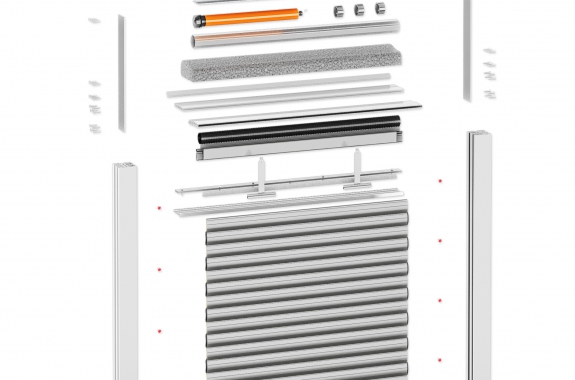

There are a number of factors on which the correct operation of external roller shutters depends, and thus their proper properties – from thermal to anti-burglary. The correct assembly is only one of them. A very important element influencing the correct behaviour of the systems is also the way they are manufactured, and especially whether the process takes place according to the system provider's guidelines.

Manufacturer's know-how

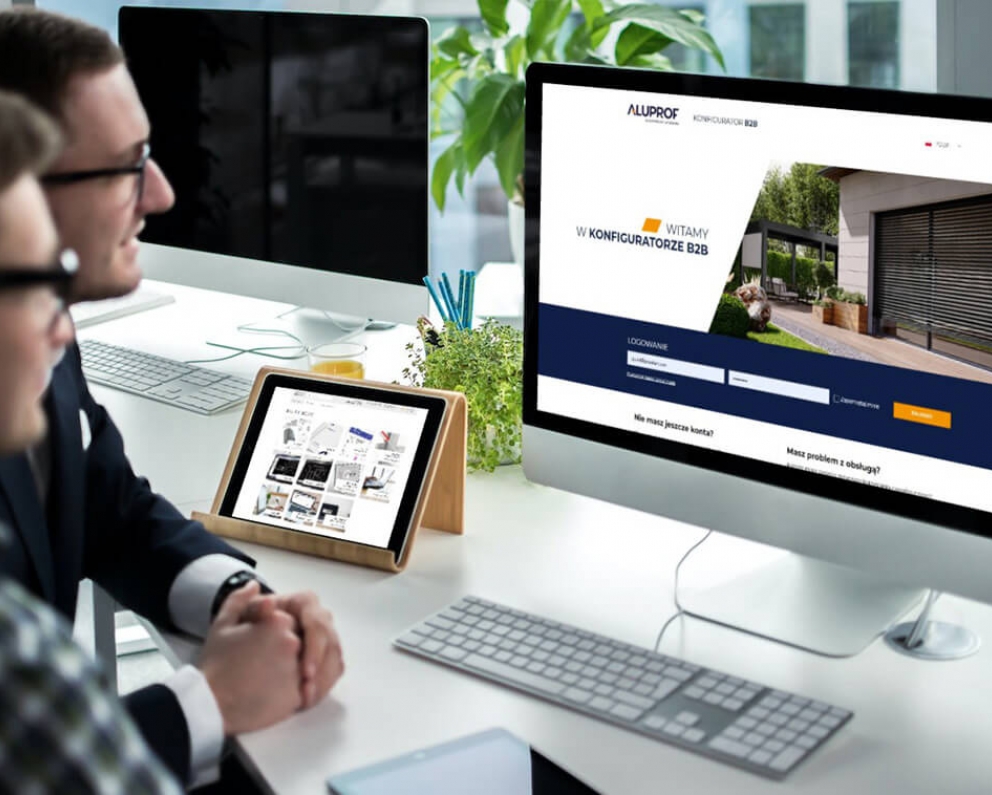

Aluprof, like other system providers, provides its business partners with a complete set of technical information, expertise and practical production solutions in addition to components for the production of external roller shutters and rolling gates. Nevertheless, some manufacturers often use components from different system providers in the prefabrication process, usually for habit or economic reasons. However, as practice shows, this is only an apparent saving, as a non-systemic approach may result in inconsistent details, and thus, frequent failures and services.

What are the threats of a non-systemic approach?

A non-systemic approach to system prefabrication can have serious consequences. Seemingly identical looking elements may differ in both quality and functionality. It is enough to change the type of material from which a given detail is made (e.g. cap, pulley or plugs) to see that it can have a huge impact on the entire product. What does this mean for the quality of the entire product? For example, if the caps are too brittle, they will crack, and if the plugs are made of plastic, which absorbs moisture from the environment, we will have to deal with swelling and delaminating shutter curtain. Any differences in construction are also important. Even slight inclinations or curves can make it difficult or impossible to connect components that have not been tested for their suitability. It often happens in practice that a properly functioning set is affected by dimensions of even ten decimal places. In this way, the connected elements can work with too much loose space, which may ultimately lead to faster wear of the individual elements or the connection will not be possible at all, because the space will be too small for the product to work properly.

Unsettled production technology

It is also worth remembering that the production of products inconsistent with system recommendations has a significant impact on the production technology. For the proper functioning of the product it would be necessary to use different lengths of cuts for individual components than those provided by the supplier of the complete system, which some manufacturers do not take into account at all. In addition to technical considerations, aesthetic considerations also play an important role. If the individual elements are connected with each other, and they do not cooperate perfectly with each other, it will unfortunately translate not only into the functionality of the product but also into aesthetics. Apart from the factors mentioned above, it is worth remembering that in the case of non-systemic completion of the product, the manufacturer loses the warranty for individual components.

The most common errors of manufacturers

The use of non-systemic elements in the prefabrication of products may have a negative impact on their functioning. Popular errors usually concern elements such as:

1. Guide channels and gaskets in the guide channels – different sizes of the chamber where the curtain is located are reflected in its operation. In case when they are too narrow, the curtain works with evident resistance, and if they are too loose, the curtain may wave.

2. Retainer springs – incorrectly selected can scratch and abrade the paint from the curtain, and badly fitted springs will cause incorrect profile breaking.

3. Endslat – too small endslat will cause waving of the curtain, and too thick will block it.

4. Bearing and entry guides – incorrectly selected will cause falling out of the roller shutter from the guide channel.

5. Profile of a roller shutter, gate or grille – profiles of different thickness or shape will not work properly in the guide channels, and will cause a disturbance of the product properties (e.g. transmission of the wind load zones).

6. Round reel – each of the reels is characterized by individual deflection parameters and compatibility with accessories.

7. Insect screen – incorrectly selected seal, hinges or net will cause the insect screen to fall out or tear and open the free path for insects.

Non-systemic approach and type testing

Unfortunately, few manufacturers are aware of the fact that any change of components during production results in manufacturing of a completely new product. It has completely different properties than products that would be created with the technology provided by the system provider. Thus, when placing such products on the market, their characteristics should be confirmed by appropriate examinations at the accreditation unit at own cost. Aluprof type examination certificates will not be binding here. Therefore, in order to save time and money, it is worth to benefit from the complete technology offered by our company.